Protein-amylose/amylopectin Molecular Interactions during High-moisture Extruded Texturization toward Plant-based Meat Substitutes Applications

Recently, the Innovation Team of Plant Protein Structure and Function Regulation, Institute of Food Science and Technology, Chinese Academy of Agricultural Sciences (IFST, CAAS), has clarified the protein-amylose/amylopectin molecular interactions during high-moisture extrusion processing and the “sub-layer transformation” mechanism toward generating meat-like textures. The relevant research results were published in the journal Food Hydrocolloids with the title “Protein-amylose/amylopectin molecular interactions during high-moisture extruded texturization toward plant-based meat substitutes applications”.

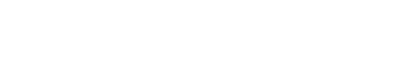

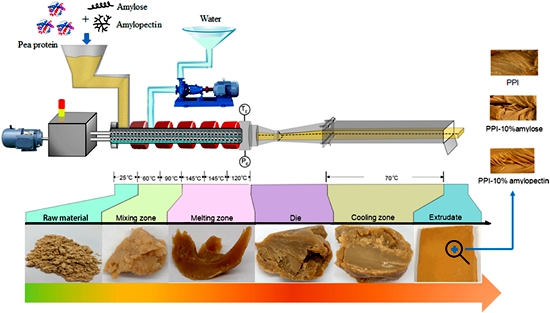

The plant protein-based meat substitutes have aroused great attention for their benefits in terms of environment protection, animal welfare and personal health. The high-moisture (>40%) extrusion (HME) method has been one of the most promising technologies for production of plant protein-based meat substitutes due to its versatility, high productivity, retention of nutrition, low energy input and no waste discharge. However, it is still difficult to reconstitute meat substitutes with proteins and polysaccharides that could be comparable to the real meat, especially in the aspect of juicy mouthfeel and the perceived tenderness, which were the key factors restrained current applications and consumers’ acceptability. Here, the interactions between proteins with amylose/amylopectin during high-moisture extrusion processing were investigated simultaneously from thermodynamics/hydrodynamics to molecular conformation changes, as well as from scientific to application-oriented points of view. Results showed that the protein gelled in the melting zone and the gel became layered after flowing from the extruder barrel, because of the phase separation between the protein and starch due to thermodynamic incompatibility. Then, “sub-layer transformation” cross-linking among the layered protein chains occurred to form fibrous structures. The cooling die (consisting of the die and cooling zone), which can also provide shear stress perpendicular to the extrusion direction, may promote the separation of the macromolecules into a continuous (protein matrix) and a dispersed phase (starch), which contributed to the formation of fibrous structures. During this processing, the amylopectin promoted the disruption of intra- and inter-molecular interactions of heat-induced aggregates and the unfolding of vicilin and legumin chains in the die. This favored protein rearrangement, aggregation and cross-linking through improved hydrophobic interactions in the cooling zone to further promote the meat-like fibrous structures formation. In contrast, phase separation of amylose and protein matrix in the die enhanced the self-aggregation and refolding of protein molecules and resulted in more rigid and denser structures. Then, the amylose gel that filled in the protein matrix resulted in steric hindrance for the protein rearrangement and cross-linking, consequently leading to a layered rough gel structure. It suggested that starch with high ratios of amylopectin, such as waxy corn starch, would be better for generating protein fibrous structures, paving the way to the application of starch in the formulation of plant protein-based meat substitutes. In total, these observations into mechanistic interactions during extrusion provide improved strategies toward generating meat-like textures and desired tenderness in processed plant materials.

This work was supported by the National Key Research and Development Plan of China (2021YFC2101402), the National Natural Science Foundation of China (31901608), and the Science and Technology Innovation Project of CAAS (CAAS-ASTIP-2020-IFST).

Fig. 1. Schematic illustration of high moisture extrusion process

Fig. 2. FTIR-FPA images of PPI-10% amylose (a) and PPI-10% amylopectin (b) mixtures in each zone during high-moisture extrusion processing

Link to the paper: https://doi.org/10.1016/j.foodhyd.2022.107559

By Shi Aimin (shiaimin@caas.cn)

-

Apr 18, 2024Opening Ceremony of the Training Workshop on Wheat Head Scab Resistance Breeding and Pest Control in Africa Held in CAAS

Apr 18, 2024Opening Ceremony of the Training Workshop on Wheat Head Scab Resistance Breeding and Pest Control in Africa Held in CAAS -

Apr 03, 2024IPPCAAS Co-organized the Training Workshop on Management and Application of Biopesticides in Nepal

Apr 03, 2024IPPCAAS Co-organized the Training Workshop on Management and Application of Biopesticides in Nepal -

Mar 28, 2024Delegation from the School of Agriculture and Food Science of University College Dublin, Ireland Visit to IAS, CAAS

Mar 28, 2024Delegation from the School of Agriculture and Food Science of University College Dublin, Ireland Visit to IAS, CAAS -

Mar 25, 2024Director of World Food Prize Foundation visited GSCAAS

Mar 25, 2024Director of World Food Prize Foundation visited GSCAAS -

Mar 20, 2024Institute of Crop Sciences (ICS) and Syngenta Group Global Seeds Advance Collaborative Research in the Seed Industry

Mar 20, 2024Institute of Crop Sciences (ICS) and Syngenta Group Global Seeds Advance Collaborative Research in the Seed Industry