Rheological Properties of Pea Protein Isolate-amylose/amylopectin Mixtures and the Application in the High-moisture Extruded Meat Substitutes

Recently, the research team of Wang Qiang, an innovation team for plant protein structure and function regulation, clarified the relationship of rheological properties of pea protein isolate-amylose/amylopectin mixtures with the product qualities of high-moisture extruded meat substitutes, simultaneously from both scientific as well as application-oriented point of view. The relevant research results were published in the journal Food Hydrocolloids (IF: 9.147).

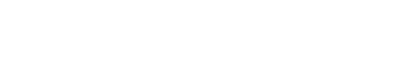

The plant protein-based meat substitutes have aroused great attention for their benefits in terms of environment protection, animal welfares and personal health. There has been an explosion of interest in application of pea protein in meat substitute production, for its advantages of abundant availability, high bioavailability, low sensitization and no beany flavor. Nevertheless, the formation of meat-like fibrous structures and the tenderness mouthfeel of meat substitutes within processed pea proteins and amylose/amylopectin components remains challenging. Here, the rheological properties of pea protein isolate (PPI, 90%)-amylose /amylopectin (10%) mixtures and its effect on the high moisture extrusion processing and the final product qualities, including the appearance, texture properties and the digestibility were investigated. Results showed that the addition of amylopectin could reduce the viscosity, storage and loss modulus of PPI. It could improve the degree of grafting and promote the formation of fibrous structures in extrudates, but reduced the in-vitro protein digestibility. However, amylose had no significant influence on the apparent viscosity of PPI and promoted the formation of a more compact structure after heating and cooling. The addition of amylose decreased the degree of grafting in PPI extrudates and was not conducive to the fibrous structure formation. Furthermore, both amylose and amylopectin addition could significantly reduce the die pressure and torque in high-moisture extrusion processing, and decrease the color difference, hardness, springiness, and chewiness of the extrudates. These results suggested that the amylopectin was beneficial for preparing the pea protein-based meat substitutes with rich fibrous structure.

Our PhD student Chen Qiongling and assistant researcher Zhang Jinchuang were co-first authors, and Professor Wang Qiang as corresponding authors. This work was supported by the National Natural Science Foundation of China (31901608), the National Key Research and Development Plan of China (2016YFD0400200), and the Science and Technology Innovation Project of Chinese Academy of Agricultural Sciences (CAAS-ASTIP-2020-IFST).

Fig. 1. Schematic illustration of high moisture extrusion process.

Link to the paper: https://doi.org/10.1016/j.foodhyd.2021.106732

By Shi Aimin (shiaimin@caas.cn)

-

Apr 18, 2024Opening Ceremony of the Training Workshop on Wheat Head Scab Resistance Breeding and Pest Control in Africa Held in CAAS

Apr 18, 2024Opening Ceremony of the Training Workshop on Wheat Head Scab Resistance Breeding and Pest Control in Africa Held in CAAS -

Apr 03, 2024IPPCAAS Co-organized the Training Workshop on Management and Application of Biopesticides in Nepal

Apr 03, 2024IPPCAAS Co-organized the Training Workshop on Management and Application of Biopesticides in Nepal -

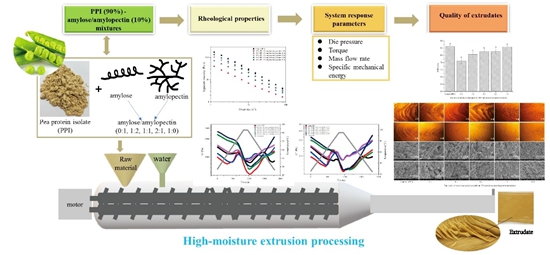

Mar 28, 2024Delegation from the School of Agriculture and Food Science of University College Dublin, Ireland Visit to IAS, CAAS

Mar 28, 2024Delegation from the School of Agriculture and Food Science of University College Dublin, Ireland Visit to IAS, CAAS -

Mar 25, 2024Director of World Food Prize Foundation visited GSCAAS

Mar 25, 2024Director of World Food Prize Foundation visited GSCAAS -

Mar 20, 2024Institute of Crop Sciences (ICS) and Syngenta Group Global Seeds Advance Collaborative Research in the Seed Industry

Mar 20, 2024Institute of Crop Sciences (ICS) and Syngenta Group Global Seeds Advance Collaborative Research in the Seed Industry